Genuine Parts

At Kobelco, we always recommend and ensure availability of Genuine & Reliable Spares for all our machines, countrywide.

- Home

- Genuine Parts

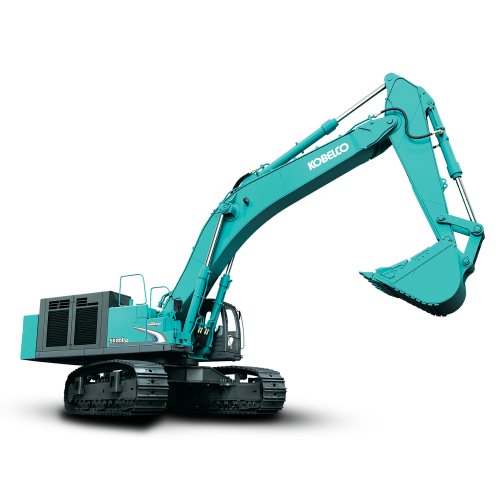

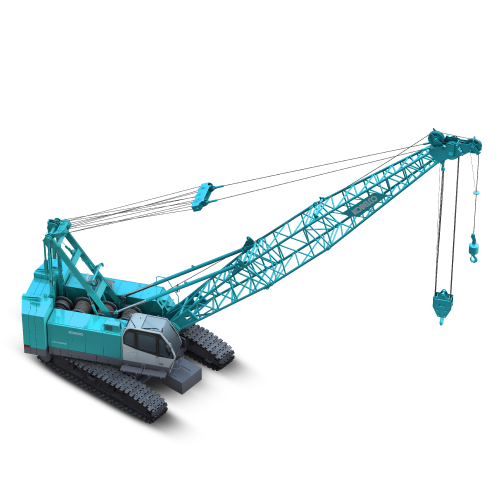

At Kobelco, we have a strong focus on critical areas such as machine uptime, productivity, and reliability.

The quality of parts and service support is directly related to the machine uptime, productivity, and reliability. Kobelco has a strong focus on these critical areas and is fully committed to providing the best support to customers, even in remote locations, through their large network of Dealer Branches and Outlets. This is reflected in the high percentage of repeat orders and positive references.

The reliability and performance of a new machine are factors of the quality of production as well as of the selected components. As such, the equipment is able to deliver its best performance in its initial hours of operation. Thereafter, as and when some parts require replacement, it is of utmost importance that the replacement parts are of the same quality as the original parts being replaced, so that machine performance level is maintained. “Genuine Parts” serve this crucial function and help in maintaining machine efficiency at par with the original. Customers are often approached with alternate parts/ ‘will-fit’ parts which may appear similar or may have matching dimensions but may not deliver the same level of performance and reliability. It may also trigger the failure of any related parts or assemblies, causing avoidable breakdowns and consequent loss of productive machine hours.

Engine Parts

Current engine technologies have transformed the landscape with respect to deliverables. While power expectations have actually increased, the operating efficiency of the engine had to be enhanced to new levels of fuel efficiency and minimal levels of effluents to fulfill increasingly stringent emission norms. Every manufacturer has had to find innovative ways to develop the right combination of metallurgy, engine dynamics, mechatronics, lubrication, etc. to achieve the desired objective of offering a high-performing, highly reliable, non-polluting Engine. It is obvious that in such a scenario if any of the component parts or elements are altered, the consequences could be very impactful and may place the entire equipment at the risk of major breakdowns.

Regular maintenance has become absolutely critical. Kobelco has identified the perfectly matched set of parts, accessories, and lubricants that can deliver the best performance. Use of the “exactly right” part is now vital for ensuring the operating efficiency of the Engine. In fact, one wrong part could cause serious damage to not just the related parts but the entire Engine. Most of our customers have experienced the high reliability of our engines with a service life much longer than others.

60,000+ working hours

GROUND ENGAGING TOOLS

Kobelco Buckets are designed to handle all types of site conditions and have performed quite satisfactorily. There is a regular demand for Kobelco Buckets in the aftermarket mainly due to their high performance and cost-effective pricing. The Bucket profile is most suitable for efficient digging as well as re-handling work. The Buckets are fitted with side-cutters so that the fill factor is quite high, enabling the Operator to achieve higher outputs. Also, for greater operational efficiency, the Bucket acts as an extension of the Boom & Arm to match the fast pace of working of Kobelco Excavators.

The productivity of any Excavator is dependent on the type and quality of the adopted ground engaging tools. Kobelco uses very effective, high performance Tooth Points and Adapters to ensure the machine can deliver the desired output in a wide variety of strata. The Adapters are welded on to the edge of the Bucket and the Tooth Points are locked in place with Pin and Washer. With their longer service life, Kobelco Tooth Points ensure low operating cost for the user. The cost per hour is very affordable.

UNDERCARRIAGE PARTS

The undercarriage is one of the major cost factors in the total operating cost of a Hydraulic Excavator. The selection of Undercarriage components and parts which work together as a ‘system’ are well-matched with the basic design parameters of the complete equipment. It is therefore of paramount importance that any worn out part is replaced with the original replacement part to maintain the performance level of the machine as a whole. Any compromise by way of fitment of any local or non-recommended part can have serious consequences including failure of not just the replaced part but also of the related parts causing breakdown of the entire machine.

The productivity of any Excavator is dependent on the type and quality of the ground engaging tools adopted. Kobelco uses very effective, high performance Tooth points and Adapters to ensure that the machine can deliver the desired output in a wide variety of strata. The Adapters are welded on to the edge of the Bucket and the Tooth points are locked in place with Pin and Washer. Kobelco Tooth points ensure low operating cost for the User with its longer service life. The cost per hour is very affordable. Regular care and maintenance of the entire Undercarriage is most essential for realizing the maximum service life and machine uptime, and to reduce the total cost of operation.

PINS AND BUSHES

Considering the nature of operation of Hydraulic Excavators, attachment Pins & Bushings are considered high-wear parts which require frequent lubrication to minimize wear due to metal-to-metal contact. Kobelco Pins and Bushings are designed meticulously for maximum service life with highly efficient provision for the spreading of grease between the surfaces for minimal wear. Kobelco Genuine Grease used at regular predetermined intervals will enhance the service life of Pins & Bushings, thereby limiting the hourly cost of operation.

Any compromise by way of fitment of any local or non-recommended part can have serious consequences including failure of not just the replaced part but also of the related parts causing breakdown of the entire machine.

GENUINE OIL

Oils and lubricants are the life-line of the equipment, very similar to the blood in our system! With the rapid progress in Engine and Fluid technologies, the role of lubricants has become vitally important in achieving desired performance levels, mainly with respect to operating efficiency and reliability of major components as well as fulfillment of stringent emission norms. For the convenience of our valued customers, Kobelco Lubricants, including Grease and Coolant, have been introduced and are available at all our Dealer Outlets in suitable packs. Kobelco Lubricants have been developed through a collaborative effort from the design stage itself. The additives used are in perfect sync with the needs of the relevant components and are aimed at ensuring their best performance and reliability subject to regular maintenance services using genuine filters and oils as per the recommended schedules.

Reconditioning

In a market which is becoming increasingly competitive, there is a need to keep the machine operating costs within control. One of the options adopted to achieve this objective is the use of ‘reconditioned parts’ instead of a new part. Such reconditioned parts are made under factory conditions after replacing all service parts and necessary testing to ensure proper functionality. One can achieve a substantial cost reduction without any significant reduction in performance and reliability.

Component Overhauls

All components and aggregates have a primary service life during which they perform with almost the original operating efficiency, provided scheduled maintenance services are carried out regularly. However, for better utilization and to achieve a higher ROI on the original investment, Kobelco recommends preventive overhauls by trained engineers using genuine repair / replacement parts, carried out at proper workshops equipped with suitable facilities. All the wear parts are replaced irrespective of their condition, so that the overhauled component can perform with comparable efficiency and reliability as the original component. Kobelco also repairs failed components depending on the estimated repair cost being viable.