Overview

Mechatronic simulator training module is best in class which provides realism experience to trainees resulting in an engaging learning experience that become beneficial to enhance the trouble shooting skill at job sites. Trainees can learn faster through simulator Mechatronic simulator operation board is like an actual machine. It consists of:

- Operation levers

- Lever lock safety switch

- Battery disconnection switch

- Travel operation leverKPSS switch

- Swing parking brake release switch

- Engine throttle for KPSS mode

- Engine speed dial

- Key switch

- DPF regeneration switch

Benefits of learning through simulator

- It provides realism which enables trainees to get more idea about system of actual machine.

- It eliminates the risk of damage to actual machine.

- It is compact & movable and always available for training.

- In house practical training is possible through simulator only.

- As compared to training on actual machine, more numbers of trainee can take training at a time.

- Simulator are easier to control.

- Economical in operation, reduce cost and time.

- Helpful as a refresher opportunity for employees looking to strengthen their skills.

- Through simulator, Trainees will become able to apply theory and principle in to practice and further enhancing knowledge retention.

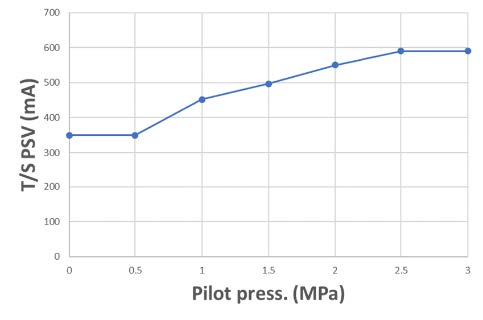

Measure the command current to Travel-straight PSV at each pilot pressure of Boom-up.

And make a graph. The conditions are:

– Engine speed: 2,000rpm

– Main pressure: 12MPa at P1&P2

– Pilot pressure: 3.0 MPa at travel R&L

Features

- Trainee can check how SV and PSV is driven by a signal from the mechatro controller

- clogging level and engine water temperature can be adjusted with the dial.

- Error code and error message can be shown by using this control board.

- Clogged hydraulic oil filter and radiator level alarm are occurred by operating a switch.

- Fuel level, hydraulic oil temperature, P1 / P2 pump pressure, boom head / rod pressure can be adjusted by dial operation.

- Mechatronic software is same as actual software. (SK200-10)

- A special ECU software for mechatronic simulator is installed in mechatronic controller, and it is used as an ECU.

- Battery relay, Safety relay and Fuse BOX are same as actual machine.

- Since the simulator does not have an engine, the simulator has an engine control board to check the engine status.

- Can measure the current values at different operations and plot the graph to analyze.

| Pilot Press | T/S PSV (mA) |

|---|---|

| 0.0 | 350 |

| 0.5 | 350 |

| 1.0 | 452 |

| 1.5 | 497 |

| 2.0 | 550 |

| 2.5 | 590 |

| 3.0 | 590 |

Training at a glance

On Mechatronic simulator, below are highlighted points which covered during the training. Trainees check the parameters through gauge cluster and analyse for trouble shooting.

1. Basic control

Positive control

PQ control

Unload control

2. Operation control (Fundamental)

Bucket double flow

Bucket ant cavitation

Arm-IN double and recirculation

Arm-IN ant cavitation

Travel straight

Swing priority

Swing parking brake

3. Operation control advanced

Arm-IN double flow (Recirculation cut)

Bucket ant cavitation

Swing priority

4. Warning

Water temperature sensor

Hydraulic oil temperature

5. Trouble shooting

Bucket dig

Travel curve

Arm In and swing

Engine start

Training at Noida Training centre